Swedish research leads the way to cleaner water in Europe

The European Commission's new proposal for cleaner air and water requires stricter laws for Europe's tens of thousands of wastewater treatment plants, and time is running out. However, a solution is already in place in Sweden, in the southernmost county of Skåne. There, cutting-edge research and collaboration have pushed forward new analysis methods and pioneering facilities that are now fully operational. Moreover, the results are even better than what the European Commission requires.

The European Commission recently proposed stricter cleaner air and water regulations through the “European Green Deal”. The ambition is zero pollution; therefore, the Urban Wastewater Treatment Directive must be revised. By 2040, all water released from treatment plants for 100,000 people or more must be free of pharmaceuticals, pesticides, antibiotics, PFAS, and other harmful substances. The proposal also applies to treatment plants with at least 10,000 people in areas with sensitive nature, water sources, or other protected areas.

Two wastewater treatment plants, WWTPs, that already meet the new strict requirements in the EU Commission's proposal can be found in southernmost Sweden, in the villages of Degeberga and Kivik, both inaugurated in 2020 and equipped for the future. Ten years earlier, local fishermen in Kivik had raised the alarm about foul-smelling water, dead birds, and sore, fungal-infested fish. The situation prompted the Swedish Agency for Marine and Water Management to act. In the subsequent report, they cite a cocktail of harmful substances as one of several possible explanations.

“Continuous projects have led to the region today being the most mapped in the country.”

“We found that there was a lack of analysis data, and via the LUSKA project, funded by Region Skåne, the regional council of the county, we were able to start mapping the emissions of micropollutants in Skåne in 2016. Ongoing projects have led to the region being the most mapped in the country today,” notes Ola Svahn, a researcher in environmental analytical chemistry at Kristianstad University, working at the MoLab research laboratory.

The measured emissions of micropollutants from WWTPs, and receiving water around Skåne county show that traditional treatment plants are not built for today's chemical society and lifestyles. The WWTPs cannot remove the micropollutants, even though the levels are so low. Nevertheless, the micropollutants are harmful even at low levels, which has been a problem to measure reliably in various environmental samples. The results produced have often been questioned for various reasons.

“It has required a slightly different way of thinking to tailor robust analysis methods that suit substances with different properties and must be analyzed at such low concentrations in such tricky samples. Previous methods have probably suffered from being too general and too imprecise,” says Ola Svahn.

Ola Svahn presents the fourth purification step to the Baltic delegation. The new fourth purification step with granular activated carbon (GAC) is installed after the three traditional steps of mechanical, biological and chemical purification.

Ola Svahn presents the fourth purification step to the Baltic delegation. The new fourth purification step with granular activated carbon (GAC) is installed after the three traditional steps of mechanical, biological and chemical purification.

Old technology in Sweden's most modern treatment plant

The two WWTPs in Degeberga and Kivik are the first of their kind. They both have a fourth treatment step consisting of pretreatment and granular activated carbon (GAC), complementing the three traditional mechanical, biological, and chemical steps. This fourth treatment step removes most harmful substances that would have only traveled straight through the first three treatment steps.

“It has been critical to develop and evaluate the technology on a large scale together with both the industry and the treatment plant's operating staff.”

When Ola Svahn started researching water purification with GAC ten years ago, the technology was considered complicated to operate, expensive and inefficient, and the carbon had too short a lifespan. The focus was almost exclusively on purification through ozone. However, a lot has happened in a decade. Ola has shown that the GAC technology is cheaper and more efficient than previously thought. The measurement results indicate that filters with GAC also have a relatively long service life.

“The type of active carbon used is essential for efficiency,” Ola Svahn points out. “We established early on that the granular activated carbon surface properties are important to consider, as well as the chemical properties of the micropollutants.”

In Switzerland, researchers have also confirmed that GAC filters are an effective method for removing micropollutants in wastewater and that it is a robust and easy-to-use technology.

“It has been critical to develop and evaluate the technology on a large scale together with the industry and the treatment plant's operating staff,” says Ola Svahn. “We ran the pilot at the Kristianstad WWTP in 40,000-bed volumes. Then we are out in reality and have real conditions to develop, research and measure. It also becomes scalable in a completely different way than if we tested this in a laboratory environment.”

The delegation from Latvia and Lithuania is guided around Degeberga's new WWTP by Stefan Borg, operator on wastewater treatment in Kristianstad Municipality, that manages the facility.

The delegation from Latvia and Lithuania is guided around Degeberga's new WWTP by Stefan Borg, operator on wastewater treatment in Kristianstad Municipality, that manages the facility.

Research that attracts international interest

Patiently, the GAC technology has been evaluated, and the levels of micropollution in the Skåne waterways have been mapped at MoLab through various projects. Soon the sampling area also grew. Via the international EU projects MORPHEUS and LESS IS MORE, in which Denmark, Poland, Germany, and Lithuania were also involved, water samples from the southern Baltic Sea's watercourse came in for analysis at MoLab.

The ripples on the water continue. Recently, a delegation from Latvia and Lithuania visited Sweden to take a closer look at the WWTPs and the methods behind the purified water in Skåne. The County Administrative Board of Skåne is also far ahead and recently issued a report on how water treatment should be prioritized in the future. Now the two Baltic countries want to know what the Swedish authorities are doing about the problems, and how.

“Sweden has a lot to share. Here are successful examples of how the research is put into practice …”

“Sweden has a lot to share. Here are successful examples of how the research is put into practice through full-scale treatment plants that are now in use with treatment technology for micropollution. In the Baltics, we need this knowledge about how cooperation between different decision-making authorities, researchers, and other interest groups works,” says Sergej Suzdalev from the Marine Research Institute of Klaipeda University on the coast of Lithuania.

As in Skåne, before the LUSKA project, there was no information on pharmaceutical regulations in the Baltic states. To fill these knowledge gaps, Sergej and his colleagues initiated MEDWwater, another EU-funded project to measure levels of pharmaceuticals in wastewater, their effects, and how they can be reduced.

“Through MORPHEUS, we had the opportunity to familiarize ourselves with MoLab's analytical experience and improve our knowledge of drug residues in different sample types. There we also became familiar with the advanced and sensitive laboratory equipment required for this,” says Sergej.

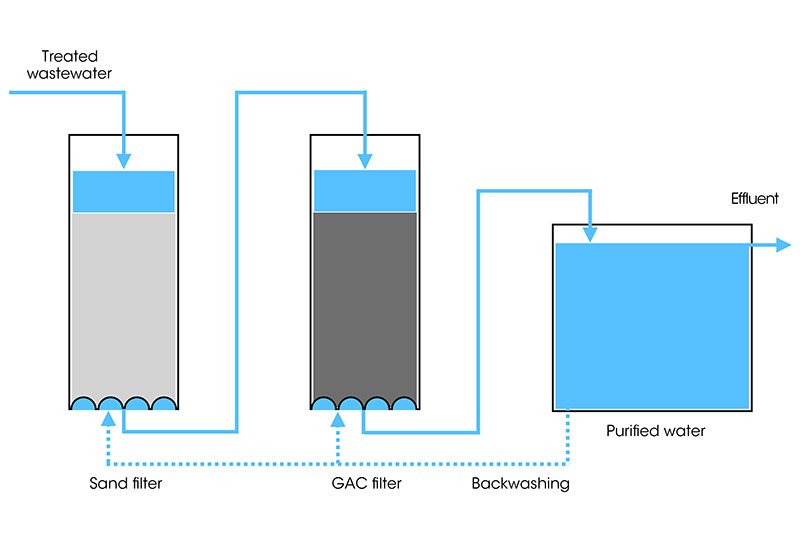

The fourth treatment step, with sand filter and GAC filter. The purified water can be reused, for instance for backwashing.

The fourth treatment step, with sand filter and GAC filter. The purified water can be reused, for instance for backwashing.

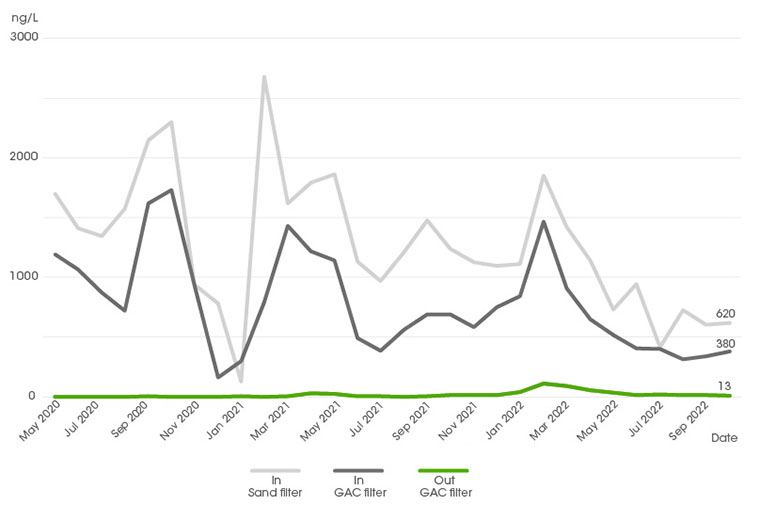

Levels of diclofenac in and out of the fourth treatment step in Degeberga, from May 2020 to October 2022. First through the sand filter and then through the GAC filter.

Levels of diclofenac in and out of the fourth treatment step in Degeberga, from May 2020 to October 2022. First through the sand filter and then through the GAC filter.

Two filters in one – both adsorption and decomposition

WWTP in Degeberga became Sweden's first full-scale treatment plant equipped with GAC, and it has been in operation for three years with the same filter. Twenty-six thousand bed volumes have passed, and so far, no filter has been backwashed, a technique to clean the filter from organic matter. A sand filter is used before the carbon to protect the active carbon from clogging. This sand filter is, in fact, Sweden's first, installed in 1973 with sand from the nearby tourist town Simrishamn.

“One of the reasons why we chose Degeberga was the existing sand filter. Several other Swedish treatment plants are already equipped with sand filters. Since Degeberga's is still, after so many years, proving to work excellently as a pre-filter, it provides savings for the large investments that are now likely to await all over Europe,” Ola Svahn points out.

Under the European Commission's proposal, the degree of purification of water leaving WWTPs must be at least 80 percent on a selected number of micropollutants. The degree of purification after almost three years, on solely the fourth purification step in Degeberga, the sand, and GAC filters, is 84 percent. However, several of the selected pollutants have a significantly higher degree of purification than that.

“Together with associate professor Michael Cimbritz's research group in sewerage technology (VA-teknik) at Lund University, we have learned more about how the active carbon filters work and how substances degrade, adsorb and compete for binding sites at different depths in the carbon bed. Carbon's capacity strongly depends on the substance's chemical properties, such as charge and water solubility,” explains Ola Svahn.

“By combining these different filters, we can achieve even better degrees of purification."

Diclofenac, the active substance in the painkiller Voltaren, which is quite an elusive substance, is now, after almost three years of using the GAC filter, at a degree of purification of 98 percent. The results testify to both high efficiency and long service life.

“Diclofenac should have broken through the filter by now and given a lower degree of purification, as, for example, carbamazepine is doing. With the help of carbon-14 methods, which were developed at Lund University, we have been able to show that the reason why diclofenac is still reduced so well after three years is that our GAC filters have gradually become a BAC filter. In this biologically activated carbon filter, substances are removed and broken down. In the same carbon filter, we get both adsorption through GAC and decomposition through BAC,” explains Ola.

“We are only at the beginning of the research on granular activated carbon. I think we will be able to refine and develop new carbon materials–new adsorbents so that the carbon becomes even more efficient. We see the need, not least in our work with PFAS, which adsorbs relatively poorly to activated carbon. In the future, filter materials will be tailored depending on the substances that need to be removed. Furthermore, by combining these different filters, we can achieve even better levels of purification, to the benefit of both the environment and human health.”

Words: Fabian Rimfors

Photo: Ola Svahn and Fabian Rimfors